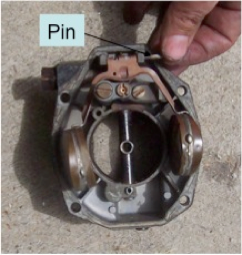

Step 5: We remove the float. There is a small pin

at the top of the float which can be taken out by

hand.

The heat separated the two halves of each side of

the float, so it had to be re-soldered. I used

plumber's solder, which I assume uses an acid core.

This was just a guess, but I imagine it will work

OK. To check the seal, I weighed the float on a

precision scale and got a weight of 17.9 grams.

Next, I held the float under water for a few hours,

took it out and dried if off. If the float had a

leak, it would have been slightly heavier.

Fortunately, it still weighted 17.9 grams, and I

concluded that it was OK.